Understanding vertical offset in installation means recognizing height differences between components to ensure proper alignment and surface evenness. You need to measure accurately using tools like laser levels or spirit levels and make small adjustments with shims or spacers. Correct management prevents uneven surfaces, operational issues, and misalignments. Developing a systematic approach helps you identify and fix issues early. Want to discover detailed techniques and best practices? Keep going to learn more about ensuring perfect vertical alignment.

Key Takeaways

- Vertical offset is the height difference between components that affects proper alignment and installation quality.

- Accurate measurement tools like laser levels and spirit levels are essential for managing vertical offset.

- Establishing a reference baseline helps ensure consistent vertical alignment throughout the installation process.

- Adjustments using shims or spacers can correct minor height discrepancies caused by material imperfections.

- Proper handling of vertical offset prevents uneven surfaces, operational issues, and costly rework.

Vertical offset in installation refers to the difference in height between components or surfaces that need to be aligned. When you’re working on a project, whether it’s installing cabinetry, setting up machinery, or laying out structural elements, understanding this concept is essential to ensure everything fits and functions properly. If you overlook vertical offset, your installation could end up uneven, causing operational issues or aesthetic flaws. That’s why paying attention to measuring accuracy and employing proper alignment techniques are fundamental steps in the process.

Measuring accuracy is the foundation for managing vertical offset effectively. You want your measurements to be precise because even small errors can lead to significant misalignments later on. Use high-quality tools like laser levels, spirit levels, or digital measuring devices to get reliable readings. When measuring, always double-check your figures to confirm consistency, especially when working with multiple components. Remember, small inaccuracies in measurement can compound, resulting in noticeable offset issues once everything is assembled. Taking your time and verifying measurements at each step helps prevent costly mistakes and ensures the components will line up perfectly.

Precise measurement is crucial to prevent offset issues and ensure perfect alignment during installation.

Once you’ve gathered accurate measurements, applying the right alignment techniques becomes your next focus. Start by establishing a reference point or baseline, which acts as your standard for height and position. From there, you can use string lines, laser guides, or spirit levels to transfer this reference across your workspace. When adjusting components, do so incrementally, checking your measurements frequently to confirm you’re maintaining the correct height. If you’re working with multiple surfaces, use shims or spacers to fine-tune their positions and eliminate any vertical offset. These small adjustments can make a significant difference in achieving a seamless, level installation.

In some cases, you’ll need to account for the natural imperfections in materials or surfaces, which might cause slight deviations. Here, understanding how to compensate for these irregularities using alignment techniques is essential. For example, if a surface isn’t perfectly flat, you might need to adjust neighboring components or add shims to bring everything into alignment. Always keep your measuring tools close by during adjustments to verify progress and prevent overcorrecting. Developing a systematic approach to measuring accuracy and alignment ensures you catch issues early, saving time and material costs down the line. Additionally, awareness of filtration effectiveness in related components can help ensure your overall setup maintains optimal performance and longevity.

Official Licensed Google TV Smart Projector, HAPPRUN 4K UHD Home Theater with Dolby Sound, Wi-Fi & Bluetooth, Built-in Streaming Apps, Compatible with Games Consoles & Smartphone, Indoor & Outdoor Use

[ Built-in Official Licensed Google TV ] - Without additional equipment, the smart projector can directly access Netflix,...

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Does Vertical Offset Affect Overall Installation Safety?

Vertical offset can compromise your installation safety by creating uneven load distribution, which stresses the structure and weakens its integrity. When you overlook vertical adjustments, it risks structural failure or accidents, endangering everyone nearby. Ensuring proper alignment maintains structural integrity and promotes safe installation. Always check and correct vertical offset to prevent safety hazards, safeguard the installation, and uphold safety standards. Your attention to this detail is essential for overall safety.

Can Vertical Offset Be Adjusted After Installation?

Yes, you can adjust vertical offset after installation using various adjustment techniques. To make post-installation corrections, you’ll typically need to loosen certain components, realign the parts, and then secure everything again. It’s essential to follow manufacturer guidelines and guarantee safety during these adjustments. Properly addressing vertical offset ensures peak performance and safety, preventing potential issues caused by misalignment. Always double-check your work before resuming regular operation.

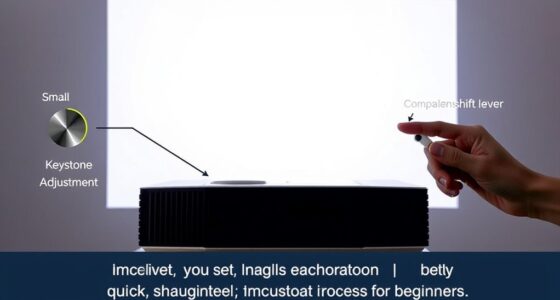

What Tools Are Best for Measuring Vertical Offset Precisely?

You’ll want precision devices like laser levels or digital measuring tools for accurate vertical offset measurement. Did you know laser levels can achieve millimeter accuracy over long distances? These measuring tools are ideal because they provide quick, precise readings, reducing errors. Use a laser level to project a straight line or digital calipers for close measurements. Investing in quality measuring tools guarantees your installation aligns perfectly, saving time and preventing costly adjustments later.

Are There Industry Standards for Acceptable Vertical Offset Ranges?

Yes, industry standards specify acceptable ranges for vertical offset, guaranteeing proper installation and safety. Typically, these standards vary by application and industry, but they generally recommend offsets within a few millimeters to maintain structural integrity and functionality. You should always consult relevant codes or manufacturer guidelines for your specific project to ensure compliance with these acceptable ranges, avoiding potential issues caused by excessive vertical offsets.

How Does Vertical Offset Impact the Durability of the Installation?

Vertical offset can jeopardize material stability, leading to uneven load distribution that stresses the structure. When offsets are significant, they cause parts to bear uneven loads, increasing the risk of material fatigue or failure over time. To guarantee durability, you should minimize vertical offsets during installation, maintaining proper alignment. This approach helps preserve material stability and ensures that load distribution remains balanced, ultimately extending the lifespan of your installation.

Pyle 6.5-Inch Wall Mount Waterproof Bluetooth Speaker System – Indoor/Outdoor Audio Pair with Built-in Digital Amplifier, Weather-Resistant Housing, High-Power Sound, Easy Installation (Black)

Includes (2) Speakers (Active & Passive Speaker System) - Marine Grade Waterproof Construction.Mounting Type:Wall Mount.Speakers maximum output power:300...

As an affiliate, we earn on qualifying purchases.

Conclusion

Understanding vertical offset is vital for a precise installation, making sure everything lines up perfectly. Did you know that improper alignment can lead to 30% more maintenance issues over time? By paying attention to vertical offsets, you save yourself from costly repairs and guarantee a smooth process. Keep in mind, a small misalignment now can cause big problems later. So, take the time to get it right—you’ll thank yourself down the road.

Homcine Projector Ceiling/Wall Mount White, Low Profile Universal Projector Holder/Bracket/Hanger Kit with Extendable Arm, Adjustable Height Pole Drop Ceiling Quick Release for Epson Optoma Benq

🎬【Upgraded cable management, safely contained】 The projector mounts adopt a large square tube design which helps keep HDMI,...

As an affiliate, we earn on qualifying purchases.

QualGear Pro-AV QG-KIT-S2-3IN-W Projector Mount Kit Accessory Suspended Ceiling 2'x2' Adapter, White

Suitable for suspended/drop ceilings

As an affiliate, we earn on qualifying purchases.