To stay compliant with fan noise and heat codes, you need to understand industry standards like ANSI/ASHRAE 70 and ISO 3744, and ascertain your system meets local regulations. Proper installation, vibration damping, airflow optimization, and regular maintenance are key to avoiding violations. Measuring sound levels, vibrations, and temperatures helps verify compliance and identify issues early. Keep up with updates and best practices—if you explore further, you’ll learn how to keep your system safe, efficient, and code-compliant.

Key Takeaways

- Understand and follow ANSI/ASHRAE Standard 70 and ISO 3744 for noise and vibration limits.

- Ensure proper fan installation, mounting, and damping to minimize noise violations.

- Review local building codes and standards like IMC and NFPA for heat output and temperature compliance.

- Conduct regular measurements and testing with calibrated tools to verify system performance and identify issues.

- Maintain thorough documentation of components, testing results, and inspections to support compliance efforts.

Silicone Speaker Isolation Feet (4-Pack, 1") – Non-Skid Adhesive Pads for Turntable, Subwoofer & Audio Gear – Anti-Vibration Damping, 20 Duro Rubber

REDUCE VIBRATION and RESONANCE. Absorbing up to 95.32% of vibration and resonance, Hudson Hi-Fi’s Isolation Feet offer an...

As an affiliate, we earn on qualifying purchases.

Understanding the Basics of Fan Noise Levels

Understanding fan noise levels is essential because excessive noise can impact comfort and compliance with regulations. To control noise effectively, focus on vibration damping methods that reduce mechanical vibrations transferring to surrounding structures. Proper vibration damping minimizes noise generated by the fan’s motor and blades, improving overall quietness. Additionally, airflow efficiency plays a vital role; when airflow is optimized, fans operate smoothly with less turbulence, which decreases noise levels. Poor airflow can cause uneven vibrations and increase noise, making it harder to meet standards. By addressing both vibration damping and airflow efficiency, you can better manage fan noise, creating a quieter environment while maintaining performance. Enhanced airflow management techniques can further optimize noise reduction and operational efficiency. When selecting fans, considering noise level ratings helps ensure they meet your desired comfort standards. This foundational understanding helps you select and maintain fans that balance noise control with operational needs. Incorporating personality insights into equipment management can also improve team collaboration and troubleshooting efficiency. Additionally, understanding the source of noise can guide targeted interventions to further reduce disturbance. Recognizing sound frequency characteristics can help tailor noise mitigation strategies for specific environments.

ZAVOOS 8 Pack Rubber Anti Vibration Pad, 4'' x 4'' x 7/8'' Heavy Duty EVA Sound Isolation Pads, Square Mechanical Vibration Damping Mat Floor Protector for Washing Machine, Dryers, Treadmill

Package Info: You will receive 8 pieces anti-vibration pads, each measures 4''L x 4''W x 7/8''Th. Sufficient quantity...

As an affiliate, we earn on qualifying purchases.

Key Standards and Regulations for Fan Noise

Regulations and standards set clear limits on acceptable fan noise levels to guarantee environments remain comfortable and compliant. These standards focus on sound attenuation and vibration control to minimize disturbance. Key regulations include ANSI/ASHRAE Standard 70 and ISO 3744, which specify maximum noise levels for HVAC systems. They also emphasize vibration damping to prevent noise transmission. To meet these standards, you should prioritize proper mounting, damping materials, and soundproofing components. Here’s a quick overview:

| Standard | Focus Area | Key Requirement |

|---|---|---|

| ANSI/ASHRAE 70 | Sound attenuation | Max dB levels in occupied spaces |

| ISO 3744 | Vibration control | Limits on vibration transmission |

| Local Regulations | Compliance & safety | Varies by region |

Adhering to these ensures your fans operate quietly and within legal limits.

4 Pack of Anti Vibration Pads 4" x 4" x 7/8" Rubber/Cork Vibration isolation pads

4 pack of Anti Vibration pads Rubber & Cork 50 PSI max load

As an affiliate, we earn on qualifying purchases.

Identifying Heat Code Requirements for Ventilation Systems

To guarantee your ventilation systems meet safety and efficiency standards, you need to identify and comply with heat code requirements that govern their design and operation. Heat codes specify the maximum allowable heat output and temperature limits for ventilation systems, ensuring they don’t overheat or cause safety hazards. Start by reviewing local building codes and standards, such as those from the International Mechanical Code (IMC) or National Fire Protection Association (NFPA). These documents detail ventilation requirements including airflow capacity, heat dissipation, and temperature controls. It’s essential to understand how these regulations apply to your system’s size, location, and purpose. Code compliance is critical for avoiding potential legal and safety issues related to ventilation systems. By accurately identifying and adhering to heat code standards, you ensure your ventilation system operates safely, efficiently, and in compliance with legal requirements. Understanding industry trends aids in maintaining code compliance and optimizing system performance.

Preffair Audiophile Speaker Isolation Spikes Aluminum Record Player Shock Absorber Speaker Floor Protector Mat Adjustable Subwoofer Anti Vibration Pads Non-Slip LP Vinyl Record Player Base

❖ Material: Aluminum; Size: OD44.5mm(1.75") x Height 33mm(1.3"); Heat Treatment Hardness: HRC50-55; Weight: 65g * 4 / Set;...

As an affiliate, we earn on qualifying purchases.

Common Noise and Heat Code Violations to Watch For

Many common violations of noise and heat codes stem from improper system design or installation. Excessive fan noise often results from incorrect fan sizing, poor duct alignment, or inadequate mounting, which can lead to noise complaints and non-compliance. Proper fan installation is critical to minimize noise levels and ensure compliance with regulations. Ensuring that ventilation system components meet manufacturer specifications can prevent many issues related to noise and heat. Proper system testing and balancing during installation can identify potential problems before the system is finalized, reducing the risk of violations. Heat violations happen when ventilation systems don’t meet required exhaust rates or fail to properly control heat buildup, risking safety and code enforcement actions. Overly noisy fans or insufficient venting can also cause heat to accumulate, creating unsafe conditions. These issues usually stem from neglecting manufacturer specifications or skipping thorough testing during installation. To avoid violations, you need to ascertain your system is correctly designed, properly installed, and regularly maintained, keeping noise levels and heat emissions within permitted limits. Proper system maintenance plays a crucial role in ensuring ongoing compliance and optimal operation. Additionally, understanding heat code requirements helps prevent violations related to heat management.

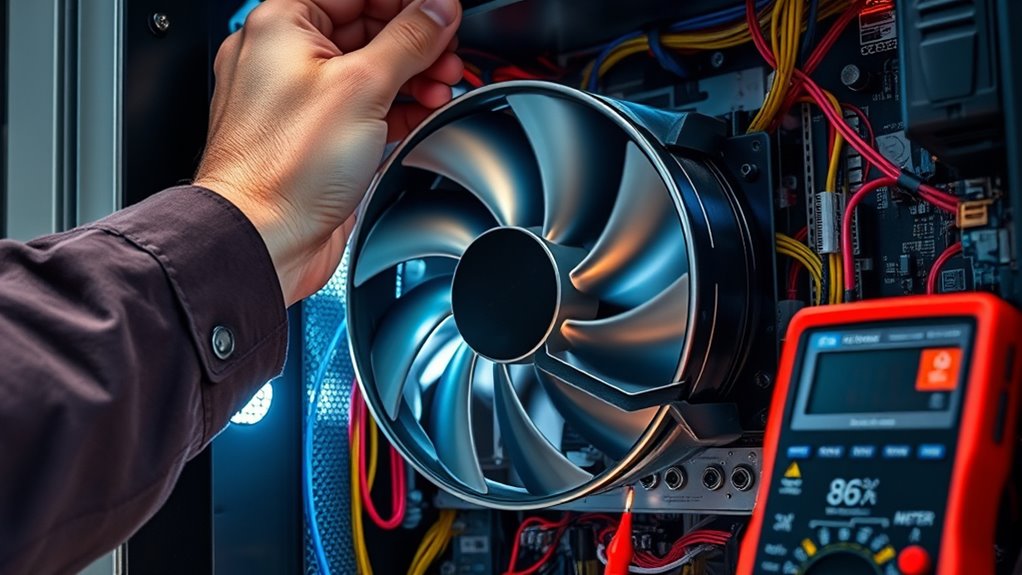

Practical Tips for Ensuring Compliance During Installation

Ensuring compliance during installation starts with meticulous planning and attention to detail. Begin by inspecting the fan blade for smooth, balanced operation to prevent excessive noise. Confirm that the fan blade is securely mounted and properly aligned. Pay close attention to motor insulation; it must meet safety standards to avoid overheating and electrical hazards. Use appropriate mounting hardware to minimize vibrations, which can lead to noise violations. Ensure the fan’s electrical connections adhere to code requirements, reducing the risk of heat build-up. Label and document all components during installation for future inspections. Regularly check that motor insulation remains intact and free of damage. Additionally, incorporating inspection protocols and digital literacy into training can help technicians stay updated on safety standards and best practices. Being aware of regulations and standards related to heat and noise levels is essential for compliance and safety. Understanding protective styling benefits can also inform safer installation practices and maintenance routines. Conducting comprehensive inspections periodically can help identify potential issues early and maintain adherence to noise and heat regulations. By focusing on these details, you help maintain compliance, improve performance, and extend the lifespan of your fan system.

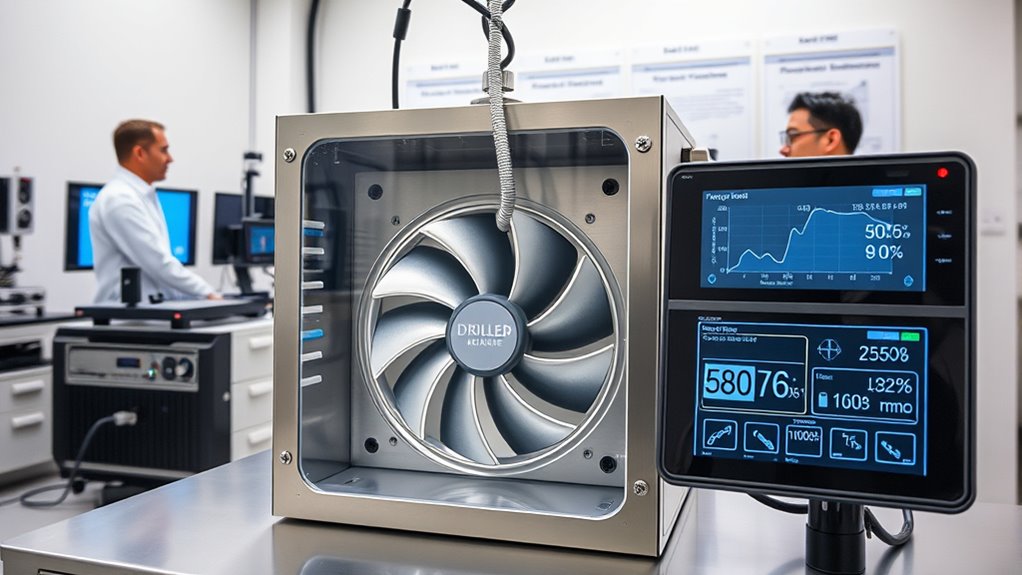

Testing and Measuring Fan Noise and Heat Performance

To accurately assess fan noise and heat performance, you need to choose the right measurement tools. Establish clear testing procedures to guarantee consistent results, and then analyze the data to identify any issues. This approach helps you verify compliance and optimize your system’s performance effectively. Proper test setup is essential to obtaining accurate and reliable measurement data. Additionally, understanding tuning options specific to your vehicle model can further enhance performance assessments.

Selecting Measurement Tools

Choosing the right measurement tools is crucial for accurately evaluating fan noise and heat performance. To assess noise levels effectively, use sound level meters that provide precise readings of decibel levels near the fan. For vibration analysis, select accelerometers or vibration sensors to detect abnormal vibrations caused by fan blade imbalance or misalignment. These tools help you identify issues that can increase noise and reduce efficiency. When measuring heat, infrared thermometers or thermal cameras are essential for pinpointing hot spots on fan components or heat sinks. Ensuring your measurement tools are properly calibrated guarantees reliable data, and understanding thermal performance metrics is vital for maintaining optimal system operation. Incorporating industry standards into your testing procedures can further ensure accuracy and compliance. Proper calibration of measurement tools is essential to obtain reliable data, which is fundamental for diagnosing issues effectively. Accurate measurement tools are the foundation for compliance and peak performance in fan systems.

Establishing Testing Procedures

Establishing effective testing procedures is vital for consistently measuring fan noise and heat performance accurately. Begin by implementing acoustic modeling to predict sound behavior in real-world environments, helping identify potential noise issues early. Use standardized testing setups to guarantee repeatability, and incorporate sound attenuation materials to minimize external interference. These materials, such as insulation or barriers, help isolate the fan’s noise, providing clearer measurements. Document all testing conditions, including airflow rates, temperature, and ambient noise levels, to maintain consistency across tests. Regular calibration of measurement instruments is essential for accuracy. By establishing clear protocols that incorporate acoustic modeling and sound attenuation materials, you ensure reliable, comparable data that supports compliance and performance assessments.

Analyzing Performance Data

Once testing procedures are in place, analyzing the performance data becomes key to understanding fan noise and heat output. Focus on airflow enhancement by reviewing airflow measurements to identify bottlenecks or inefficiencies. Use vibration analysis to detect irregularities that may indicate imbalance or mechanical issues contributing to noise and heat. Comparing data across different tests helps you pinpoint areas where improvements can reduce noise levels and enhance cooling performance. Look for patterns in the data to identify correlations between airflow, vibrations, and temperature spikes. Accurate analysis allows you to make informed adjustments, ensuring your fan system operates quietly and efficiently while meeting compliance standards. This process is essential for achieving ideal performance and maintaining reliable, compliant operation.

Navigating Permits and Documentation for Compliance

Navigating permits and documentation is a critical step in ensuring your fan installation complies with safety and regulatory standards. First, familiarize yourself with the permitting processes specific to your location, which often involve submitting detailed plans. Second, gather all necessary documentation requirements, such as technical data sheets, safety certifications, and installation diagrams. Third, submit your application ahead of time, allowing for review and approval before starting work. Visualize your project as a three-step journey: 1) researching local codes, 2) assembling precise paperwork, and 3) securing approvals. This process helps avoid delays or fines, ensuring your fan system meets all heat and noise regulations. Staying organized and proactive simplifies compliance and keeps your project on track.

Troubleshooting and Reducing Fan Noise in Existing Systems

After securing the necessary permits and documentation, it’s time to focus on maintaining ideal system performance by addressing fan noise issues. Start by inspecting the fan blades for damage or imbalance, as worn or bent blades can cause excessive noise. Ensure blades are clean and properly aligned to reduce turbulence. Vibration mitigation is key—tighten loose mounting bolts and add vibration dampers if needed. Check for loose components that may rattle or vibrate during operation. If noise persists, consider balancing the fan blades or replacing worn parts. Regular maintenance, including lubrication and cleaning, can considerably reduce noise levels. By identifying sources of vibration and addressing them promptly, you’ll improve airflow efficiency and create a quieter, more reliable system.

Staying Updated on Changes in Noise and Heat Regulations

Staying current with changes in noise and heat regulations is essential to guarantee your systems remain compliant and efficient. To keep up, you should:

- Regularly review updates from local authorities on fan noise mitigation standards.

- Subscribe to industry newsletters that highlight new heat code enforcement policies.

- Attend training sessions or seminars focusing on recent regulation shifts.

These steps help you adapt your systems proactively, avoiding penalties and ensuring peak performance. Monitoring updates ensures you’re aware of new limits on fan noise levels and heat emissions, allowing you to make necessary adjustments. Staying informed keeps your equipment compliant, reduces the risk of violations, and improves overall system reliability. Consistent vigilance is your best defense against falling behind on compliance with evolving noise and heat codes.

Frequently Asked Questions

How Do Fan Noise and Heat Codes Impact Overall Building Safety?

Fan noise and heat codes directly impact your building’s safety by guaranteeing HVAC systems operate efficiently and quietly, which boosts HVAC efficiency and maintains good indoor air quality. When these codes are met, you reduce the risk of overheating or system failures that could compromise safety. Plus, compliant noise levels prevent disturbances, creating a safer, healthier environment for occupants. Following these standards helps you avoid penalties and ensures your building remains safe and compliant.

Are There Specific Penalties for Non-Compliance With Fan Noise Standards?

Yes, there are specific penalties for non-compliance with fan noise standards. If you disregard noise penalties, you risk fines or legal actions from compliance enforcement authorities. These penalties can vary depending on your location and severity of the violation. To avoid issues, guarantee you meet all noise regulations, and stay updated on local codes. Proper compliance not only prevents penalties but also promotes a safer, more comfortable environment.

What Are the Long-Term Benefits of Adhering to Heat Code Requirements?

Following heat code requirements is like planting seeds for a healthier future. You’ll enjoy long-term benefits such as improved energy efficiency and better indoor air quality, which can reduce your energy bills and create a safer, more comfortable environment. By adhering to these standards, you protect your property’s value, minimize repair costs, and contribute to a sustainable space that supports your well-being for years to come.

How Can Homeowners Verify if Their Ventilation Systems Meet Regulations?

You can verify if your ventilation system meets regulations by checking for compliance verification labels or documentation from your installer. Review the system’s specifications to make sure they align with local ventilation standards. Additionally, consult your local building authority or conduct a professional inspection to confirm your system’s compliance. Regular maintenance and testing help ensure ongoing adherence to regulations, keeping your home safe and efficient.

What Emerging Technologies Are Improving Fan Noise Reduction and Heat Compliance?

Imagine a world where fan noise is barely a whisper — that’s what emerging tech like smart sensors and advanced acoustic materials are making possible. These innovations actively monitor noise levels and optimize performance, ensuring compliance with heat and noise regulations. Smart sensors detect issues in real-time, while acoustic materials absorb sound, creating quieter environments. Together, they’re revolutionizing fan systems, making heat management and noise reduction smarter, more efficient, and virtually invisible.

Conclusion

By mastering the basics, monitoring your metrics, and maintaining your systems, you’ll make compliance a cinch. Stay savvy about standards, swiftly spot violations, and smoothly streamline solutions. With consistent checks and current knowledge, you’ll conquer noise and heat hurdles with confidence. Keep learning, keep leveling up, and let your ventilation ventures venture forward flawlessly, free from fuss. Your commitment to compliance creates a calmer, cooler, and compliant space to thrive.