When choosing screen materials, you’ll want to consider options like mesh for durability or fabric for flexibility and privacy. It’s crucial to follow safety standards set by bodies like OSHA, UL, and CE for fire resistance, toxicity, and chemical safety. Proper testing and certifications ensure compliance and safety, while best practices include regular inspections and adhering to regional regulations. Keep exploring to discover how these standards help you select safe, long-lasting screens that meet all codes.

Key Takeaways

- Different screen materials like mesh and fabric have unique durability, safety, and environmental characteristics affecting code compliance.

- Regulatory bodies such as OSHA, ANSI, UL, and CE set standards for safety, fire resistance, and chemical toxicity of screen materials.

- Testing procedures verify materials meet safety, fire, UV stability, and impact resistance standards, ensuring compliance.

- International standards promote compatibility and quality, requiring adherence to regional safety codes and certifications.

- Proper installation, regular inspections, and adherence to safety guidelines ensure ongoing compliance and user safety.

Types of Screen Materials and Their Characteristics

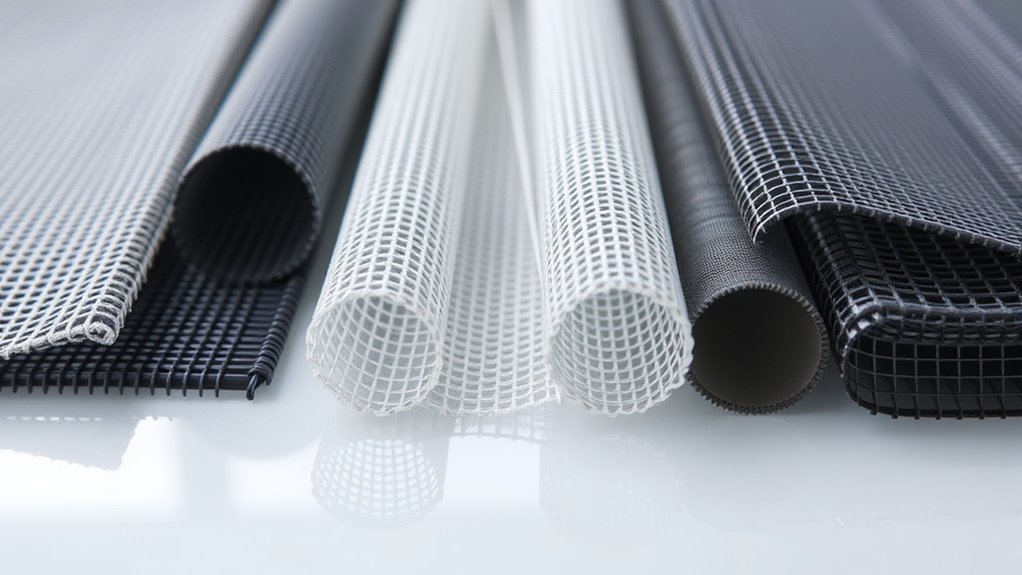

When choosing a screen material, it’s important to understand the different types available and their unique qualities. Mesh screens are known for their durability, making them ideal for high-traffic areas or outdoor use where resistance to tearing and weather is essential. They typically withstand harsh conditions better than other materials, ensuring long-lasting performance. On the other hand, fabric screens excel in flexibility, providing a softer, more adaptable option. This flexibility allows for easier installation and the ability to create custom shapes or sizes. Some fabrics also offer better light filtration and privacy. Additionally, selecting eco-friendly materials can support biodiversity conservation by reducing environmental impact. Understanding the different screen types and their characteristics—mesh durability and fabric flexibility—can help you select the right screen material to meet your specific needs, whether durability or adaptability is your priority. For example, considering environmental sustainability can influence your choice toward eco-friendly options that minimize ecological footprints. Moreover, incorporating advanced manufacturing techniques can enhance the performance and lifespan of your chosen screen material.

Key Safety Standards and Regulatory Bodies

You need to understand the safety standards that protect you when selecting screen materials. OSHA safety regulations set the minimum requirements, while ANSI standards provide detailed guidelines for performance and safety. International compliance bodies guarantee products meet global safety criteria, helping you choose reliable and compliant screens. Recognizing essential oil safety considerations can further ensure proper use and handling of materials associated with screen manufacturing or maintenance. Incorporating diverse design options can also enhance the effectiveness and safety of screen materials in various environments. Additionally, understanding storage and expiration guidelines for related products can prevent potential hazards and ensure longevity of the materials used. Being aware of operating hours for suppliers or service providers can assist in timely maintenance or sourcing of materials, ensuring ongoing compliance and safety. Moreover, understanding standardized testing procedures helps validate that screen materials meet the necessary safety and performance benchmarks, fostering confidence in their use.

OSHA Safety Regulations

Have you ever wondered which organizations set the safety standards that protect workers on the job? OSHA, the Occupational Safety and Health Administration, is the primary regulatory body responsible for enforcing safety regulations in workplaces across the U.S. They establish guidelines for various industries, including those involving window tinting and soundproofing installations. OSHA’s standards ensure that workers use appropriate protective equipment, follow safe procedures, and minimize hazards like exposure to harmful chemicals or excessive noise. These regulations help create safer work environments, reducing accidents and injuries. When working with screen materials, understanding OSHA’s safety requirements is vital for compliance and protecting everyone involved. Staying informed about OSHA standards helps you maintain safety while handling and installing materials that may involve tinting or soundproofing techniques. Additionally, awareness of cybersecurity vulnerabilities, such as those highlighted during the recent Microsoft Outage Impact, can be crucial for protecting digital safety data in the workplace. Understanding safety standards and how they are enforced can also help prevent legal issues and ensure a safe working environment for all employees. Being familiar with industry safety regulations can further support compliance efforts and promote a culture of safety. Moreover, following best safety practices can significantly reduce the risk of workplace accidents related to screen material handling and installation. Recognizing the importance of workplace hazard identification is essential for proactively addressing potential risks before they result in incidents.

ANSI Standards Overview

While OSHA sets many workplace safety standards, the American National Standards Institute (ANSI) plays a vital role in developing voluntary consensus standards that complement regulatory requirements. ANSI standards focus on ensuring that screen materials meet criteria for safety, durability, and performance. These standards guide manufacturers in producing screens with optimal durability, so they withstand daily use without compromising safety. Creativity is also essential in designing innovative screen solutions that meet both aesthetic and safety needs. Additionally, ANSI emphasizes aesthetic appeal, ensuring screens are visually pleasing while maintaining strong safety features. By adhering to ANSI standards, you can ensure your screens are both safe and attractive, reducing the risk of failure or injury. These standards help balance safety, durability, and aesthetic appeal, giving you confidence that your screen materials meet recognized benchmarks for quality and compliance. Understanding safety standards is essential for selecting reliable and compliant screen materials. Proper compliance with industry standards can also facilitate smoother approval processes and enhance customer trust, especially when considering product testing and certification to verify safety claims. Furthermore, following ANSI guidelines can help manufacturers stay ahead of emerging regulatory requirements, ensuring ongoing compliance as safety regulations evolve.

International Compliance Bodies

International compliance bodies establish the key safety standards and regulations that govern screen materials across different regions. These organizations ensure your screens meet international expectations for durability and color consistency, preventing issues like cracking or fading. By adhering to these standards, you can confidently select materials that perform reliably worldwide. The table below highlights major compliance bodies and their focus areas: | Organization | Region | Focus Areas | |———————|——————-|——————————| | IEC (International Electrotechnical Commission) | Global | Safety, durability, testing | | UL (Underwriters Laboratories) | North America | Safety, fire resistance | | CE (Conformité Européenne) | Europe | Compliance, quality control | | ISO (International Organization for Standardization) | Global | Quality, consistency | Understanding these bodies helps ensure your screens maintain high standards of safety, durability, and color consistency across markets. Additionally, standardization efforts by these organizations promote compatibility and interoperability of screen materials worldwide. Implementing these standards can also facilitate market access and reduce trade barriers for manufacturers.

Fire Resistance and Flammability Requirements

Understanding fire resistance and flammability requirements is essential when selecting screen materials, as these standards help guarantee safety in case of a fire. You need to consider whether the material is fire retardant, meaning it resists ignition and slows the spread of flames. Flammability testing is a critical process that evaluates how materials respond to fire exposure, ensuring they meet safety codes. Materials that pass these tests are less likely to contribute to fire hazards, protecting occupants and property. Keep in mind that different jurisdictions may have unique fire resistance standards, so verifying compliance is vital. By choosing screen materials with appropriate fire retardant properties and passing flammability testing, you reduce risks and enhance overall safety in your environment.

Toxicity and Chemical Safety Regulations

When selecting screen materials, it’s crucial to take into account their toxicity and compliance with chemical safety regulations, as exposure to hazardous substances can pose health risks. Understanding chemical hazards helps you choose materials that meet safety standards and reduce potential health issues. Toxicity testing is essential to evaluate whether a material releases harmful chemicals under normal use conditions. Regulations like OSHA and EPA set guidelines to limit exposure to toxic substances, ensuring your safety and compliance. Always review material safety data sheets (MSDS) and certificates of conformity to verify that the materials have undergone proper toxicity testing. By prioritizing chemical safety, you minimize health risks and ensure your environment remains safe and compliant with relevant chemical safety standards.

Testing Procedures and Certification Processes

Understanding testing standards and methods helps you guarantee screen materials meet safety and quality benchmarks. Certification processes guide you through compliance tracks, confirming that products adhere to regulations. By following these procedures, you can confidently verify that your screens are both safe and reliable.

Testing Standards and Methods

Testing standards and methods guarantee that screen materials meet safety, quality, and performance requirements before they reach consumers. These procedures ensure screens withstand daily use, maintain durability, and support proper installation techniques. To understand these standards better, consider these key aspects:

- Material strength testing for screen durability

- Fire resistance evaluations

- UV stability assessments

- Flexibility and impact resistance checks

Certification and Compliance Tracks

Once screen materials pass the necessary testing standards, they must undergo certification and compliance processes to verify they meet all regulatory requirements. This involves durability testing to ensure the materials can withstand normal use without degrading, which confirms their long-term performance. During certification, authorities review labeling requirements, making sure labels clearly display safety information, standards met, and manufacturer details. You’ll need to submit documentation proving your products have passed relevant tests, including durability assessments, to receive official certification. This process guarantees your screen materials are compliant with industry regulations, reducing safety risks and legal issues. Completing certification not only guarantees product quality but also builds consumer trust, helping your business meet safety standards and gain market access effectively.

Best Practices for Ensuring Compliance and Safety

To guarantee compliance and safety when selecting and installing screen materials, you need to follow established regulations and best practices diligently. Prioritize understanding local codes and manufacturer guidelines to ensure proper installation. Consider design aesthetics to match your environment without compromising safety. Always assess cost considerations, balancing quality and budget constraints. Additionally, verify that the materials used are fire-resistant and UV-protected when required.

Here are key best practices:

- Verify materials meet safety standards and certifications.

- Keep updated with evolving regulations and codes.

- Incorporate design aesthetics that do not compromise safety.

- Conduct regular inspections for wear, damage, or deterioration.

Following these steps helps you create a safe, compliant, and visually appealing environment.

Frequently Asked Questions

How Often Should Screen Materials Be Inspected for Safety Compliance?

You should inspect your screen materials at least once a year for safety compliance. Maintain a regular inspection schedule to catch any wear or damage early. During each safety testing frequency, check for tears, loose frames, or sharp edges that could pose hazards. If you notice any issues, repair or replace the materials promptly. Regular inspections help guarantee your screens stay safe and functional, preventing accidents and ensuring compliance.

Are There Specific Labels Indicating Compliance on Screen Materials?

Yes, there are specific labels indicating compliance on screen materials. You should look for clear label requirements that include material identification, such as safety standards or certification marks. These labels help you verify that the screen material meets safety codes and regulations. Always check for the appropriate labels before installation, ensuring the material is compliant and suitable for your project, which helps maintain safety and code adherence.

Can Non-Compliant Screens Be Legally Installed in Commercial Buildings?

You might think non-compliant screens are fine to install, but in reality, they’re not legally permitted in commercial buildings. Skipping compliance checks can lead to hefty fines or safety issues down the line. So, if you want to avoid trouble, always guarantee your screens meet the necessary codes. Installing non-compliant screens isn’t just risky—it’s illegal, and compliance isn’t optional, even if it seems inconvenient.

What Are the Penalties for Failing to Meet Safety Standards?

If you fail to meet safety standards, you could face significant penalties. Penalties overview includes hefty fines, potential legal action, and project delays. Safety violation consequences can also involve mandatory corrections, increased insurance premiums, and even work stoppages. Ignoring safety requirements not only risks injury but can lead to costly setbacks. It’s essential to adhere to all safety regulations to avoid these penalties and protect everyone on-site.

How Do Updates in Regulations Affect Existing Screen Installations?

Regulatory updates can impact your existing screen installations by requiring you to assess and modify setups to maintain installation compliance. When regulations change, you must review your current screens, ensuring they meet new safety standards. Staying informed about these updates helps you avoid penalties and safety issues. You might need to upgrade materials or re-install components, ensuring your screens align with current regulations and keep your space safe and compliant.

Conclusion

Remember, safety is no accident. By understanding different screen materials, adhering to safety standards, and following testing protocols, you can guarantee your projects are both compliant and secure. Stay informed about regulations and choose materials wisely—because an ounce of prevention is worth a pound of cure. When it comes to safety, don’t leave anything to chance. Keep learning, stay vigilant, and always prioritize safety first to protect yourself and others.