To quickly master color gamut, coverage codes, and compliance, start by familiarizing yourself with key color spaces like sRGB, Adobe RGB, and DCI-P3. Learn how to identify your printer’s gamut range using test patterns or software tools. Understand coverage codes such as 50%, 100%, and spot colors, and know the difference between total coverage and spot color matching. Automate verification with software and stay current on industry standards. Keep these tips in mind to ensure fast, compliant results—more tips follow to streamline your process further.

Key Takeaways

- Understand common color standards (sRGB, Adobe RGB, DCI-P3) to ensure quick compliance and compatibility across devices.

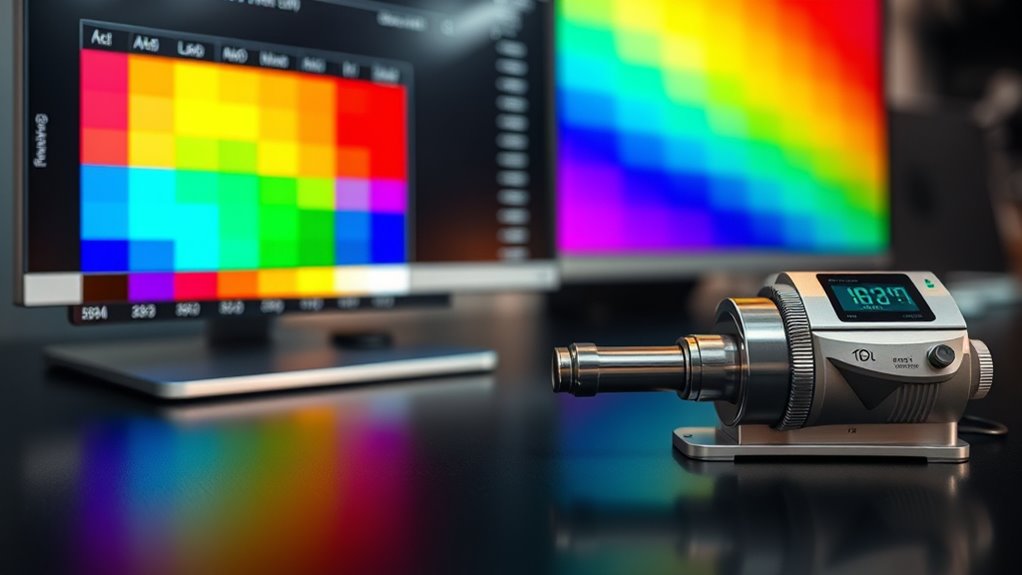

- Use standardized color profiles and calibration tools to rapidly verify device color accuracy and prevent drift.

- Recognize coverage codes (e.g., 50%, 100%) and their impact on ink and color reproduction in print projects.

- Utilize color management software to visualize gamuts and identify out-of-gamut colors for immediate correction.

- Regularly consult industry guidelines and standards to ensure quick adherence to color gamut and coverage compliance.

Understanding Color Gamut and Why It Matters

Understanding color gamut is essential because it defines the range of colors a device or medium can reproduce. When you grasp this, you improve your understanding of color perception, ensuring that your designs look consistent across different platforms. A wider color gamut allows for more vibrant and accurate colors, which is vital for effective design integration. If your device’s color gamut is limited, certain hues may appear dull or distorted, affecting how your audience perceives your work. Recognizing these limitations helps you choose the right equipment and optimize your workflow. Additionally, awareness of the financial influence of entertainment industries can guide you in selecting materials and technology that deliver the most impactful visuals. Understanding the color reproduction capabilities of your tools ensures you can achieve the intended visual effects in your projects. Being aware of asset division laws and their implications can further help you make informed decisions about production and distribution. For instance, understanding the color gamut limitations of your printing or display devices can help prevent costly reprints or adjustments. Moreover, understanding color management workflows can help you maintain color consistency throughout your production process. Ultimately, understanding color gamut empowers you to create visuals that are true to your vision, ensuring your message communicates clearly and powerfully.

Key Color Space Standards You Should Know

Understanding the key color space standards helps you guarantee accurate color reproduction across devices and media. You should familiarize yourself with common color spaces, their coverage, and the relevant industry standards and codes. This knowledge enables you to make informed decisions and maintain consistency in your projects. Being aware of Color Gamut and Coverage Codes ensures your work adheres to compliance and quality benchmarks. Additionally, understanding how Relationship dynamics can impact visual consistency helps in creating cohesive and professional outputs. Recognizing color management workflows helps streamline processes and achieve predictable results across different platforms. Moreover, mastering romantic communication techniques can significantly improve collaboration and understanding in creative projects that involve emotional expression. A solid grasp of color space standards can also aid in troubleshooting and ensuring interoperability between different devices and mediums.

Common Color Spaces

Knowing the key color spaces is essential for guaranteeing your digital and print projects meet industry standards. These spaces define how colors are represented and reproduced, directly impacting color perception. Common color spaces like sRGB, Adobe RGB, and ProPhoto RGB serve different purposes, from web design to high-end photography. Understanding their differences helps you select the right one for your project’s needs. Color perception relies on how colors are interpreted by devices and viewers, which is influenced by the pigment properties used in physical media and the digital encoding in color spaces. By mastering these standards, you guarantee accurate color reproduction and consistency across platforms. Recognizing these common color spaces helps you optimize workflows and meet industry expectations for quality. Additionally, understanding the color gamut of each space ensures your project stays within achievable color ranges, preventing color inaccuracies during reproduction. Being aware of the color space limitations allows you to choose the most suitable model for your specific application and desired output quality. Moreover, understanding the digital encoding of color spaces ensures that colors are accurately represented in digital files and displays. A solid grasp of color management principles further enhances your ability to achieve consistent results when moving between different devices and media.

To improve workflow efficiency, it’s also important to consider the monitor calibration process, which ensures your digital displays accurately reflect the chosen color space.

Color Gamut Coverage

Color gamut coverage determines how well a color space can reproduce the full range of colors your project requires. A broader gamut enhances color accuracy, ensuring that the colors you see on screen or print match your intended palette. This is critical for achieving precise color matching, especially in industries like photography, printing, and design. When selecting a color space, consider how much of the visible spectrum it covers—more extensive coverage means better fidelity and consistency across devices. Knowing the key standards, such as sRGB, Adobe RGB, and DCI-P3, helps you choose the right gamut for your specific needs. Accurate color matching depends on understanding these coverage capabilities, allowing you to deliver high-quality, vibrant visuals that meet your project’s color precision demands. Additionally, awareness of color space standards ensures your workflow remains consistent and reliable across different media and platforms. Understanding color gamuts can also guide you in properly calibrating your monitors and printers for optimal color reproduction, especially when considering device calibration techniques to maintain color fidelity over time. As technology advances, the development of new color management systems further enhances the ability to reproduce colors accurately across various devices and media. Moreover, keeping abreast of emerging color gamut expansion technologies can help future-proof your color workflows and ensure continued high fidelity.

Industry Standards and Codes

Staying aligned with industry standards and codes is essential to guarantee your project’s colors are consistent and reliable across different devices and platforms. These standards guide your color management and ensure proper color calibration, reducing discrepancies. Key color space standards include sRGB, Adobe RGB, and DCI-P3, which define the color gamut for various media. Understanding these codes helps you select the right color profile for your project’s needs. Imagine this table as a map of color worlds:

| Standard | Typical Application | Gamut Coverage | Color Depth | Calibration Focus |

|---|---|---|---|---|

| sRGB | Web, Consumer Devices | Narrow | 8-bit | Basic |

| Adobe RGB | Photography | Wide | 8-16-bit | Advanced |

| DCI-P3 | Digital Cinema | Wide | 10-bit | Precise |

| Rec. 709 | HDTV | Moderate | 8-bit | Standard |

| BT.2020 | UHD, HDR | Very Wide | 10-12-bit | High Precision |

Aligning with these standards guarantees your colors stay true, no matter the platform. Additionally, understanding the color gamut coverage of each standard helps you make informed decisions for color accuracy in your projects. Recognizing the color space differences is crucial for maintaining visual consistency across various media.

How to Identify Your Printer’s Gamut Range

To accurately determine your printer’s gamut range, start by running a calibration test using a standardized color chart or test pattern. This step is essential for effective color management, as it guarantees your printer’s output aligns with expected color standards. Once you have the test results, use color profiling software to analyze the color data. Color profiling helps you identify the specific range of colors your printer can reproduce, highlighting its gamut boundaries. Understanding these limits allows you to optimize your color workflows and avoid overestimating your printer’s capabilities. Regularly calibrating and profiling your printer ensures consistent color accuracy, minimizes errors, and improves overall output quality. This process gives you a clear picture of your printer’s color reproduction range, forming the foundation for better color management practices.

Common Coverage Codes and Their Meanings

Understanding common coverage codes helps you quickly assess print quality and compatibility. You’ll learn how to interpret coverage labels and recognize key examples. This knowledge guarantees you select the right options for your printing needs without confusion.

Common Coverage Code Types

Coverage codes serve as essential identifiers that clarify the scope and intent of color gamut and coverage specifications. They help you understand how ink formulation affects color matching and coverage. Common coverage code types include percentages, such as 100%, which indicates full coverage, and fractional codes like 1/2 or 1/4, representing coverage levels. Some codes specify the number of coats needed, such as 2-coat or 3-coat applications. Others use letter designations, like “A” for light coverage or “B” for medium. These codes streamline communication and ensure consistency across projects. Here’s a quick visual guide:

| Coverage Code Type | Meaning |

|---|---|

| Percentage (%) | Coverage amount (e.g., 50%) |

| Fractional | Coverage level (e.g., 1/2) |

| Coat Numbers | Number of ink layers applied |

| Letter Codes | Coverage intensity (A, B, etc.) |

Interpreting Coverage Labels

Have you ever wondered what a coverage label like “50%” or “1/4” really means on your ink or coating? These labels relate to how much surface area the product will cover, but they also influence your perception of color. When you see a “50%” coverage, it indicates that the pigment is mixed to provide a semi-transparent layer, affecting how light interacts with the surface and how colors appear. Understanding these labels helps you gauge how pigment mixing impacts color perception—more coverage often results in richer, more vibrant colors, while less coverage can produce a more subdued look. Proper interpretation guarantees you choose the right coverage level for your project, balancing pigment concentration with the desired visual effect and durability.

Coverage Code Examples

Coverage codes provide a quick reference for how much surface area a product will cover and the opacity you can expect. They help you manage color effectively and optimize ink use during production. For example, a code like “100” indicates full coverage, ideal for vibrant, opaque colors. Conversely, “50” suggests partial coverage, suitable for lighter shades or underlays. Here are some common coverage codes:

| Coverage Code | Meaning |

|---|---|

| 100 | Full coverage, high opacity |

| 75 | Moderate coverage, semi-opaque |

| 50 | Light coverage, semi-transparent |

Using these codes helps streamline color management and ink optimization, ensuring consistent results across projects. Understanding these examples allows you to select the right coverage levels for your specific application, reducing waste and improving print quality.

Differences Between Total Coverage and Spot Colors

Understanding the difference between total coverage and spot colors is essential for achieving accurate color reproduction in printing. Total coverage calculation measures the ink amount used across the entire print area, ensuring it stays within acceptable limits to avoid issues like ink smudging or drying problems. Spot color matching, on the other hand, involves selecting specific inks to reproduce precise colors, often outside standard color gamuts. This distinction impacts your process in three key ways:

- Total coverage affects ink layer thickness, influencing drying and adhesion.

- Spot colors require careful matching to achieve consistent branding colors.

- Both factors must be balanced to meet quality standards and compliance codes.

Knowing when to prioritize total coverage calculation versus spot color matching helps you optimize print quality and adhere to specifications effectively.

Tools and Software for Gamut and Coverage Analysis

To effectively manage color gamut and coverage, leveraging the right tools and software makes a significant difference. These tools enhance your understanding of color perception, confirming accurate color reproduction across various devices and substrates. Digital color management software helps you analyze and visualize how colors will appear in different gamuts, reducing guesswork and errors. You can compare color spaces, simulate output conditions, and verify coverage parameters before printing or production. This proactive approach saves time, minimizes waste, and ensures compliance with color standards. By integrating these tools into your workflow, you gain better control over color consistency, making your color management more reliable and efficient. Ultimately, investing in the right software streamlines your process and delivers predictable, high-quality results.

Interpreting Color Specifications in Job Files

Interpreting color specifications in job files is essential for guaranteeing accurate color reproduction across all production stages. Proper understanding helps maintain color consistency and prevents costly errors. When reviewing file formatting, pay close attention to embedded color profiles, resolution settings, and color mode (RGB or CMYK). These elements influence how colors render on different devices and substrates. To effectively interpret these specifications, consider these points:

Understanding embedded color profiles and modes ensures accurate, consistent print results.

- Verify that color profiles align with your target output standards.

- Ensure file formatting supports the necessary color data without compression or conversion issues.

- Cross-check color values against client or industry standards to confirm consistency.

Mastering this process minimizes surprises during printing, ensuring your final product matches expectations.

Practical Tips for Maintaining Color Consistency

To keep your colors consistent, start by standardizing your color profiles across all devices and workflows. Make sure to perform regular calibration checks to catch any drift in color accuracy early. Additionally, document your color settings so you can easily replicate and verify your processes over time.

Standardize Color Profiles

Standardizing your color profiles is essential for maintaining consistent color output across different devices and workflows. Proper color management ensures colors stay true, reducing surprises in final output. To achieve this, you should:

- Use standardized color profiles for your monitors and printers to ensure compatibility.

- Regularly calibrate your printer to maintain accurate color reproduction.

- Save and apply the same profiles consistently throughout your workflow.

Regular Calibration Checks

Regular calibration checks are crucial for maintaining consistent color accuracy over time. They ensure your color management stays precise, preventing drift that can affect output quality. Use reliable calibration tools designed for your specific devices—monitors, printers, or scanners—to verify and adjust color settings regularly. Establish a routine schedule, such as weekly or monthly, depending on usage intensity, to catch any deviations early. Proper calibration helps keep color profiles aligned with industry standards and client expectations. Keep detailed records of calibration results to track trends and identify when adjustments are necessary. Regular checks reduce the risk of costly reprints and ensure your color management process remains reliable, consistent, and compliant with coverage codes and standards.

Document Color Settings

Maintaining consistent document color settings is essential for guaranteeing your output matches your intended colors across different devices and workflows. Properly managing these settings helps preserve color consistency and supports your brand’s color branding efforts. To do this effectively:

- Use a standardized color profile throughout your documents to ensure uniformity.

- Always embed color profiles before sharing files, preventing color shifts.

- Regularly review and update your color settings to align with current branding standards.

How to Check Compliance With Gamut Limits

To guarantee your display complies with gamut limits, you’ll need to verify that its color output stays within the specified boundaries. Start by using color management tools and software that compare your printed or displayed colors against the target gamut. Focus on color matching accuracy, ensuring that colors are reproduced faithfully without exceeding limits. Be mindful of substrate considerations, as different materials can affect how colors appear and whether they stay within the allowed range. Use calibration charts or spectral measurement devices to analyze your output directly. Regularly checking your work helps identify out-of-gamut colors early, allowing adjustments before final production. This proactive approach ensures your colors stay consistent, compliant, and true to your intended design.

Strategies for Managing Out-of-Gamut Colors

When you identify out-of-gamut colors during your compliance checks, managing them effectively becomes key to ensuring accurate reproduction. To do this, focus on color matching and ink control techniques. First, use software adjustments to subtly shift colors closer to the printable gamut, reducing out-of-gamut issues. Second, monitor ink control to prevent oversaturation, which can cause color shifts. Third, communicate with the press team to implement real-time corrections if colors drift. These strategies help maintain consistency and accuracy. Remember, controlling ink levels and making precise color matching choices are essential for managing out-of-gamut colors and ensuring your final output meets compliance standards. Staying vigilant with these approaches minimizes color inaccuracies and improves overall print quality.

Best Practices for Optimizing Ink Coverage

To optimize ink coverage, start by managing ink limits to prevent oversaturation and waste. Use color guides to guarantee consistent application and maintain color accuracy across your prints. Applying these best practices helps you improve quality while controlling costs effectively.

Manage Ink Limits

Managing ink limits is essential for achieving consistent color quality and controlling production costs. Proper ink limit management ensures you stay within ideal coverage, preventing oversaturation that can cause issues like longer drying times or ink bleed. To improve coverage control, focus on these key points:

- Set appropriate maximum ink limits based on substrate and press capabilities.

- Regularly monitor and adjust ink levels during production.

- Use prepress tools to simulate ink coverage and avoid exceeding limits.

Use Color Guides

Using color guides is a proven method to enhance ink coverage and guarantee color consistency across your print jobs. By referring to standardized color guides, you can achieve accurate color matching, reducing the need for reprints and minimizing wasted ink. These guides help you select the right colors and determine ideal ink formulation, ensuring consistent results from batch to batch. Incorporating color guides into your workflow streamlines the process of matching colors precisely, saving time and resources. When you rely on proven standards, you reduce guesswork and improve overall quality. Regularly referencing these guides during prepress ensures your ink coverage stays within specified limits, leading to better control over ink application and a more professional final product.

Automating Gamut and Coverage Checks in Workflow

Automating gamut and coverage checks streamlines the workflow by quickly identifying color issues early in the production process. It guarantees consistent results through proper color calibration and effective ink management. Using automated tools allows you to catch problems before they escalate, saving time and resources. To maximize benefits, focus on these key points:

- Integrate color management software that automatically verifies color accuracy.

- Set up real-time alerts for coverage deviations to prevent ink wastage.

- Regularly update calibration profiles to maintain color consistency across devices.

Automation reduces manual intervention, minimizes errors, and keeps your workflow efficient. By embedding these checks into your process, you’ll improve quality control and ensure your color output always meets specifications. This proactive approach saves costs and enhances overall product consistency.

Troubleshooting Common Compliance Issues

When compliance issues arise, addressing them promptly is essential to maintain color accuracy and meet industry standards. Common problems include inconsistent color reproduction, coverage discrepancies, or unexpected color shifts. To troubleshoot effectively, review your color management workflows and ensure proper calibration. Use the table below to identify typical compliance issues and solutions:

| Issue | Solution |

|---|---|

| Color mismatches | Recalibrate monitors and printers |

| Coverage inconsistencies | Verify substrate and ink compatibility |

| Out-of-gamut colors | Adjust color profiles before printing |

| Print quality degradation | Check for clogged nozzles or dirty heads |

| Color shift over time | Regularly update calibration routines |

Staying Updated With Industry Standards and Codes

Staying current with industry standards and codes is essential to guarantee your color management practices remain compliant and competitive. By keeping up-to-date, you ensure your processes align with the latest requirements, reducing errors and avoiding costly rework. To do this effectively, consider these key steps:

- Regularly review updates from organizations like ISO, ICC, and ASTM.

- Subscribe to industry newsletters and join professional groups.

- Attend webinars and conferences focused on color management and industry standards.

Remaining informed helps you adapt quickly to changes in color gamut and coverage regulations. It also ensures your compliance efforts are accurate, supporting consistent quality and customer satisfaction. Staying updated isn’t just about compliance; it’s about maintaining your competitive edge through precise, current color management practices.

Final Tips for Fast and Accurate Gamut and Coverage Compliance

To guarantee rapid and accurate compliance with gamut and coverage standards, focus on implementing clear workflows and leveraging the right tools. Start by understanding basic color theory to predict how colors will reproduce on your chosen print substrate. This knowledge helps you select appropriate color profiles and avoid costly reprints. Always verify your color data against industry standards before printing, using calibration tools that match your print substrate’s characteristics. Keep communication open with your team to quickly spot potential issues. Regularly review your process to identify bottlenecks and ensure consistency. By combining a solid grasp of color theory with precise workflows, you’ll streamline compliance, reduce errors, and achieve reliable results faster.

Frequently Asked Questions

How Do Different Printers Affect Color Gamut Accuracy?

Different printers considerably impact your printer color and gamut accuracy. Inkjet printers often provide a wider color gamut, capturing more vibrant hues, while laser printers may have a narrower range, affecting color fidelity. The quality of the printer’s components, ink or toner, and calibration also influence how accurately your printer reproduces colors. To achieve the best color gamut accuracy, choose a printer suited for high-quality color work and regularly calibrate it.

What Are the Cost Implications of Compliance Violations?

You face significant cost impacts if you violate compliance standards, leading to fines, penalties, and costly reprints. These compliance risks can also damage your reputation and delay project timelines, adding more expenses. Non-compliance might mean investing in corrective measures or legal fees, which strain your budget. Staying compliant helps prevent these costs, ensuring smoother operations and avoiding unnecessary financial burdens due to violations.

How Often Should Color Calibration Be Performed?

You should perform color calibration regularly, ideally every 2 to 4 weeks, depending on your equipment and workload. Use reliable calibration tools to guarantee consistency, especially if you notice color shifts or workflow changes. Frequent calibration maintains color accuracy and reduces errors, saving time and money in the long run. Keep a schedule and record your calibration frequency to track any patterns or issues that might require adjustments.

Can Software Automatically Correct Out-Of-Gamut Colors?

Did you know that up to 80% of color issues can be fixed automatically? Software automation in color management can often correct out-of-gamut colors, streamlining your workflow. While it may not handle every situation perfectly, many programs adjust colors swiftly, ensuring consistency. You should still review results, but automation saves time and helps maintain accurate, vibrant colors across your projects.

What Training Is Recommended for Staff on Color Standards?

You should prioritize staff education on color theory to guarantee they understand color relationships, contrast, and harmony. Offering training sessions, workshops, or online courses helps your team grasp industry standards and best practices. Encourage hands-on experience with color management tools and software, and regularly update training to reflect new standards. This approach boosts their confidence and accuracy in maintaining color consistency, ultimately improving your overall color compliance and quality.

Conclusion

Imagine your print job as a vibrant canvas—knowing your color gamut and coverage codes guarantees every hue and detail shines through. With quick checks and familiar standards, you’ll navigate compliance effortlessly, like a skilled artist adjusting their palette mid-stroke. Mastering this process in just 15 minutes transforms your workflow from uncertain to confident, turning complex color challenges into a seamless masterpiece. Keep these tools in hand, and watch your prints come alive with clarity and precision.