Auto calibration lets you quickly keep your devices accurate with minimal effort, adjusting itself based on algorithms or reference signals, which is great for routine checks and real-time adjustments. Manual calibration gives you more control, allowing precise tweaks for critical measurements, but takes longer and requires expertise. Choosing between them depends on your needs—auto for convenience, manual for accuracy. Keep exploring to discover which method suits your situation best.

Key Takeaways

- Auto calibration offers quick setup and minimal effort, ideal for routine or non-critical measurements.

- Manual calibration provides higher accuracy and control, suitable for sensitive or critical applications.

- Auto calibration relies on algorithms and reference signals, while manual calibration involves step-by-step adjustments using standards.

- Auto calibration is less effective in complex or unpredictable environments, whereas manual calibration can be tailored to specific conditions.

- Combining both methods allows for efficient routine checks with precise adjustments when necessary.

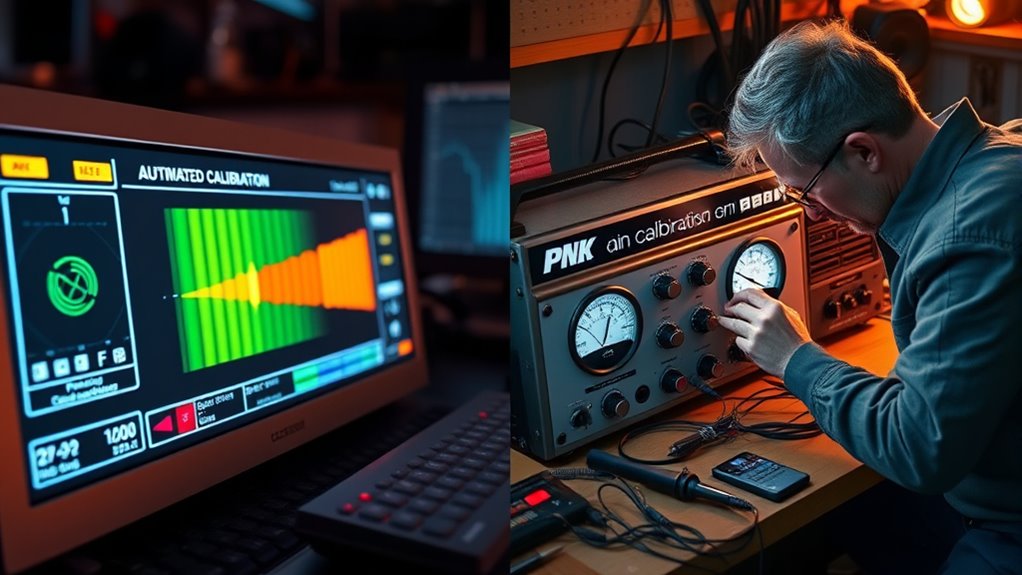

Have you ever wondered whether automatic or manual calibration is better for your equipment? When it comes to maintaining sensor accuracy, this decision can considerably impact your workflow, results, and ease of use. Auto calibration offers the advantage of quick setup and minimal effort, making it appealing if you prioritize user convenience. With automatic systems, your device adjusts itself based on built-in algorithms or reference signals, often in real-time. This means you don’t need to manually tweak settings or have extensive technical knowledge, which can save you time and reduce errors caused by human intervention.

However, the convenience of auto calibration doesn’t always translate into the highest sensor accuracy, especially in complex or highly sensitive applications. Automated systems rely on predefined parameters and assumptions that may not cover all real-world variations. If your environment is unpredictable or if your equipment demands precise measurements, relying solely on auto calibration might lead to less accurate results over time. In such cases, manual calibration can give you more control. By manually adjusting sensors, you can account for specific conditions, ensure that measurements are within tight tolerances, and tailor calibration procedures to your unique needs.

Manual calibration requires a deeper understanding of your equipment and the calibration process itself. It involves using reference standards, performing step-by-step adjustments, and carefully monitoring sensor responses. While this process might be more time-consuming and demand technical expertise, it offers the potential for superior sensor accuracy, especially when fine-tuning is necessary. Many professionals prefer manual calibration for critical measurements because it allows them to verify and optimize sensor performance meticulously, reducing drift and errors that might occur with automatic methods.

That said, the choice between auto and manual calibration often depends on the specific application, the environment, and your comfort level. If your operations involve frequent recalibration or if you need to minimize downtime, automatic calibration can streamline your workflow and provide consistent results with little effort. Conversely, if precision is paramount, taking the time for manual calibration ensures you’re getting the most accurate and reliable data possible. Ultimately, blending both methods—using auto calibration for routine checks and manual calibration for critical adjustments—can give you the best of both worlds: convenience and precision. Additionally, understanding well-being tips can help you maintain better focus and reduce stress during calibration processes, leading to more accurate results and a smoother workflow.

Frequently Asked Questions

What Industries Prefer Auto Calibration Over Manual Methods?

You’ll find industries like manufacturing, pharmaceuticals, and aerospace prefer auto calibration because it offers automated precision and improved calibration accuracy. It reduces human error, saves time, and guarantees consistent results. By choosing auto calibration, you streamline processes and maintain high standards efficiently. If your industry requires frequent calibration and strict accuracy, auto calibration is the smarter choice, providing reliable, quick, and precise measurements every time.

How Often Should Calibration Be Performed in Different Scenarios?

You should perform calibration frequently based on your equipment’s usage and manufacturer’s recommendations. For critical measurements, follow strict maintenance schedules, such as daily or weekly calibrations. Less sensitive tools might need calibration monthly or quarterly. Always consider your industry standards and environmental factors, adjusting calibration frequency accordingly to guarantee accuracy. Regular calibration helps prevent errors, maintains quality, and extends your equipment’s lifespan.

Can Auto Calibration Detect All Types of Measurement Errors?

Auto calibration improves measurement accuracy and can detect many common errors quickly, but it doesn’t catch all types of measurement errors. Some errors, like those caused by environmental factors or equipment wear, require manual inspection or specialized calibration techniques. You should regularly verify calibration results and combine auto calibration with manual checks to ensure thorough error detection and maintain high measurement accuracy.

What Are the Long-Term Cost Differences Between Auto and Manual Calibration?

Think of auto calibration as planting a seed for long-term savings; it often costs more upfront but reduces errors and minimizes labor costs over time. Manual calibration may seem cheaper initially but can lead to higher maintenance and correction expenses later. You benefit from error reduction and consistent accuracy, which can considerably lower your total long-term costs. Ultimately, auto calibration can be a smart investment, saving you money in the long run.

Are There Safety Concerns With Auto Calibration Systems?

Auto calibration systems can pose safety concerns if not properly maintained, as inaccuracies may lead to malfunctions. You should perform thorough risk assessments regularly and reliability testing to identify potential issues. Verify the system’s sensors and algorithms are validated and calibrated correctly, and monitor performance consistently. This proactive approach helps mitigate safety risks, keeping your equipment safe and reliable over time.

Conclusion

When choosing between auto and manual calibration, consider your needs for accuracy and convenience. For example, a manufacturing plant might prefer auto calibration to ensure quick, consistent results, reducing downtime. On the other hand, a lab technician might opt for manual calibration for precise adjustments in complex experiments. Ultimately, understanding your equipment and goals will help you decide which method best suits your situation, guaranteeing reliable performance every time.